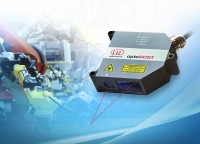

OptoNCDT 1750 sensors are powerful sensors triangulation, used for fast and precise measurements in industrial applications. New rating algorithms and enhanced components provide top accuracy and dynamics. The high-performance optical system produces a small spot of light on the measured object, which allows obtaining reliable measurements of even the smallest details.

Due to the compact design with integrated controller, this sensor can be used in a variety of applications, which simplifies simplified installation in a limited space. Data is transmitted in digital or analog version via the RS422 interface. What's more, optoNCDT 1750 provides two switching outputs and one input to control of various functions.

Service is simple and intuitive thanks to a network interface that allows easy configuration. Integrated help texts accelerate the configuration of parameters.

The laser-optical measuring system worked almost regardless of the material and color, thanks to the real-time surface compensation function. The new network interface simplifies configuration, there is no need for additional software. The user has easy-to-use presettings in the web browser, which are also optimized for difficult surfaces such as translucent plastics and ceramics, PCB materials or plastics reinforced with carbon and glass fibers. The settings enable quick commissioning and provide very precise results.

The selection of maximum points and the suppression of interference signals guarantees reliable measurements of the components of engine structures and gears covered with grease, as well as coated materials, objects behind the glass or components sealed with foil.

For users who already know optoNCDT 1700 laser sensor , the change is easy. Both are compatible, you can still use accessories and devices.

High speed measurement optoNCDT 1750 is required for the analysis of mechanical oscillations. For example, when maneuvering wagons for which the influence of bumpers is to be determined or when measuring rotating parts, for example when determining the weight of the shaft.

In laser sensors , optimized lenses have been used that improved linearity. With higher repeatability, it guarantees results with greater stability and precision. This extends the application range, from now it is possible to implement even larger quantities of solutions with high requirements of measurement technology.

See our products

optoNCDT 1700BL

optoNCDT 1700BL optoNCDT 1320

optoNCDT 1320 optoNCDT 1302

optoNCDT 1302 OptoNCDT 1900 triangulation laser sensor

OptoNCDT 1900 triangulation laser sensor optoNCDT 2300LL

optoNCDT 2300LL optoNCDT 1750

optoNCDT 1750 optoNCDT 1710/2310

optoNCDT 1710/2310 optoNCDT 1420 CL1

optoNCDT 1420 CL1 optoNCDT 1610

optoNCDT 1610 OptoNCDT 1900 LL triangulation laser sensor

OptoNCDT 1900 LL triangulation laser sensor  optoNCDT 2300BL

optoNCDT 2300BL optoNCDT 1402

optoNCDT 1402 optoNCDT 1402SC

optoNCDT 1402SC optoNCDT 1700LL

optoNCDT 1700LL optoNCDT 1700

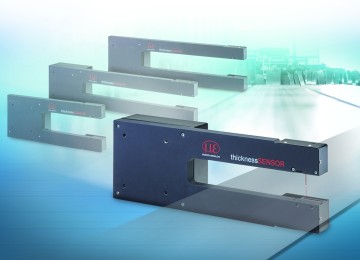

optoNCDT 1700 thicknessSENSOR - thickness measurement sensor

thicknessSENSOR - thickness measurement sensor OptoNCDT 1750-2DR laser sensor

OptoNCDT 1750-2DR laser sensor  optoNCDT 2300 Laser triangulation displacement sensor

optoNCDT 2300 Laser triangulation displacement sensor optoNCDT 1420

optoNCDT 1420 optoNCDT 2300-2DR

optoNCDT 2300-2DR OptoNCDT 1220 laser sensor

OptoNCDT 1220 laser sensor OptoNCDT 1750LL laser sensor

OptoNCDT 1750LL laser sensor optoNCDT 1630

optoNCDT 1630