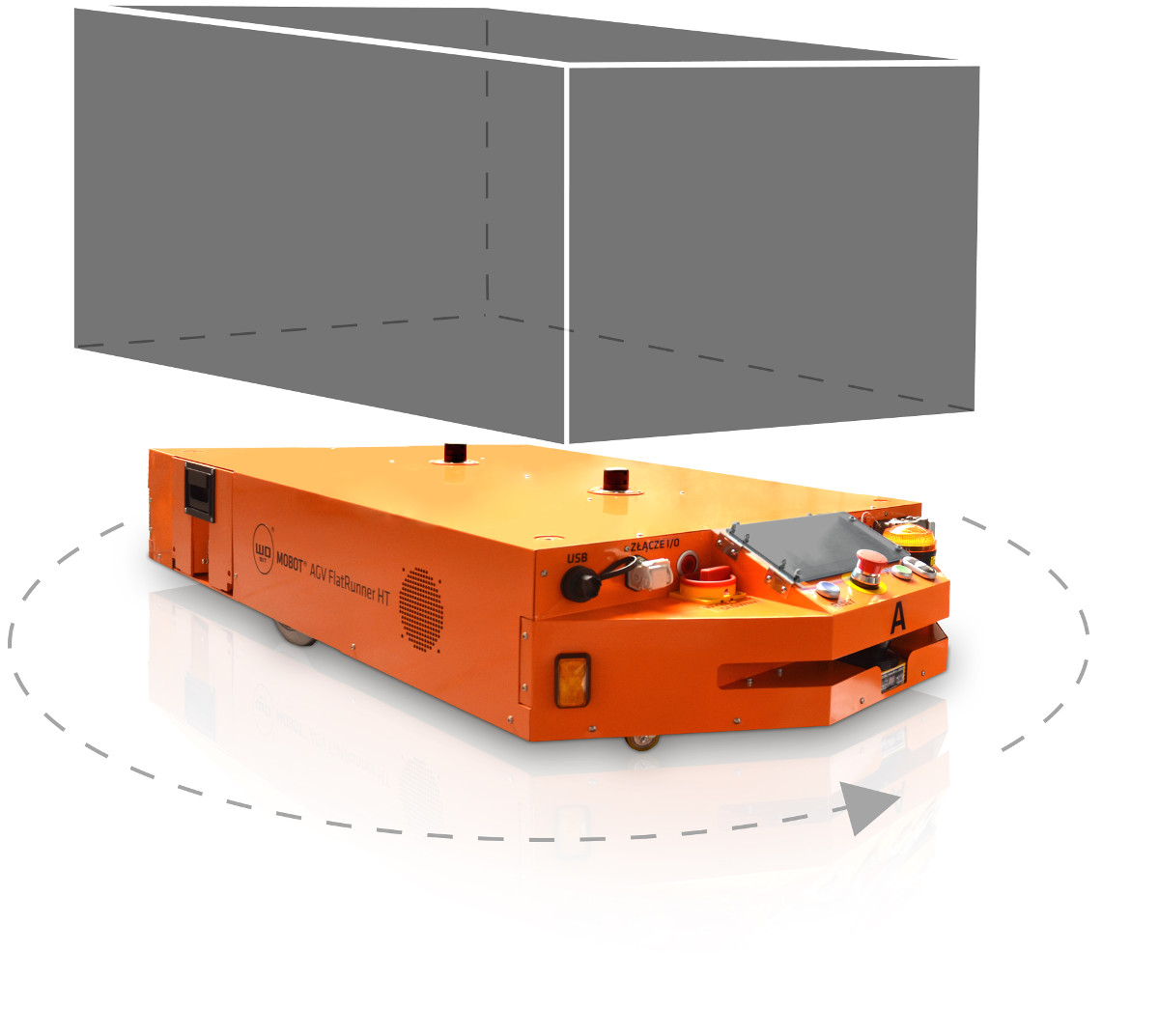

MOBOT®AGV FlatRunner HT mobile robot is used to automate internal transportation and logistics.

Its task is to autonomous transport of goods between designated points.

This model is ideally suited to automating the transport of pallets and heavy loads.

| Robot type | MOBOT® AGV FlatRunner HT(002) |

| Payload and transport method | |

| Transport method | Cart guided over the robot with the possibility of attaching using two automatic pins |

| Permissible total weight of the cart with load | 500 kg |

| Power supply | |

| Manual battery charging connector | YES (24 V DC, max. 30 A) |

| Automatic battery charging connector | A contact connector mounted on the bottom of the robot enables automatic battery charging during operation |

| Robot power supply | 2 x traction battery 85 Ah /12 V The battery is mounted in a cassette allowing for quick replacement in the robot |

| Charger | - 30 A / 24 V charger connected manually - Optional charging station with 30A / 24V charger for charging replaceable battery cartridges - Optional contact module for automatic charging |

| Operating time at full load | ~8 h |

| Operating time in standby mode | ~40 h |

| Battery charging time | ~ 3 h |

| Speed and performance | |

| Maximal speed | 3 km/h |

| Nominal power | 1200 W |

| Movement directions | Move forward / backward, turn |

| Turning radius | The possibility of turning back in place |

| Maximum surface slope | Robot designed for driving on a flat surface |

| Navigation | |

| Navigation | Navigation along the line using vision system |

| Communication | |

| Communication | 2.4 GHz Wi-Fi, optional 2.4 GHz industrial radio module (RS232) |

| Connector | - Ethernet RJ45 - communication with PC, MODBUS TCP / IP - 18 pin connector, E-Stopx2, Reset, RS485 (Modbus RTU), CANopen, 2 x input, 24 VDC power supply output (2A) + 24 VDC power supply output (10 A) |

| Drive and control | |

| Drive | 2x BLDC motor, wheels diameter 215 mm |

| Control and steering | - 1 x 7 “touch operator panel |

| Sensors | |

| Sensors | - 2 x vision system for tracking the line |

| Signaling | - 2 x light and sound signaling devices |

| Environment | |

| Operating temperature range | 5 - 45 °C |

| Humidity range | < 80 %, no condesation |

| Protection degree | IP30 |

| The intensity of external light | < 1500 lx |

| Dimensions and weight | |

| Dimensions (L x W x H) | 1600 x 750 x 239 mm |

| Total weight (with batteries) | ~220 kg |

Choose solid support and increase the efficiency of your processes.

Want to find out more? Make an appointmentThe robot is equipped with a system of two retractable pins for automatically attaching a trailer.

Automatic picking-up and delivery of pulled trucks significantly increases transport possibilities.

MOBOT® AGV can work in a variety of applications ranging from simple to very complex.

Below are the most popular examples of mobile robot traffic organization.

MOBOT® AGV FlatRunnerHT is equipped with a laser scanner with a safety function. It is responsible for detecting obstacles that appear before the AGV vehicle.

Thanks to its work, the mobile robot can respond appropriately by slowing or stopping completely to avoid collision.

We offer several models of standard trucks and adapters for the robot.

With their help, it is possible to automatically pick-up the cargo transport it safely and deliver it in the destination.

In addition to standard solutions, we also offer a truck tailored to the needs of your factory.

For FlatRunner HT navigation, we offer the laser land mapping system (LMS), or optical system with a colored line.

In the case of LMS navigation, the robot is oriented in space similar to a human being.

The robot creates a map of the surroundings in its memory and scans the space while driving, it sees characteristic points (eg, walls), thanks to which it always knows exactly where it is.

In the second method, the robot's motion route is determined by a painted or lined colored line. Characteristic points, such as stations, swings, are additionally marked by DataMatrix codes.

A video positioning system is used to track the line and recognize the control points. It allows you to precisely guide the robot and react to events (DataMatrix codes).

The work of the robot is done from the level of the control terminal placed at the base point.

Detailed configuration of the robot's parameters is provided by the intuitive MOBOTŽ RoutePlanner software.

The robot works efficiently thanks to the capacious batteries. They are placed in special cassettes, enabling their quick replacement.

The robot can also be charged using the charging station.

Optionally, it is possible to use an automatic charging station.

For the robot, we offer several models of standard trucks and adapters, including for carrying Euro pallets.

With their help, it is possible to automatically take the cargo, transport it safely and place it in the destination.

In addition to standard solutions, we also offer a truck tailored to the needs of your factory.

Benefits:

Industrial mobile robot MOBOT® AGV EcoRunner

Industrial mobile robot MOBOT® AGV EcoRunner MOBOT® AGV CubeRunner2 004 mobile robot

MOBOT® AGV CubeRunner2 004 mobile robot Industrial mobile robot MOBOT® AGV CubeRunner

Industrial mobile robot MOBOT® AGV CubeRunner Industrial mobile robot MOBOT® AGV FlatRunner

Industrial mobile robot MOBOT® AGV FlatRunner Industrial mobile robot MOBOT® AGV eRunner

Industrial mobile robot MOBOT® AGV eRunner MOBOT® AGV eRunner 003 mobile robot

MOBOT® AGV eRunner 003 mobile robot MOBOT® AGV FlatRunner 004 mobile robot

MOBOT® AGV FlatRunner 004 mobile robot MOBOT® AGV FlatRunner HT 004 mobile robot

MOBOT® AGV FlatRunner HT 004 mobile robotAre you interested in our offer? Do you want to ask a question to our adviser?

Call +48 61 22 27 422 or use the contact formuse the contact form

The WObit newsletter is a monthly knowledge and new pill for active clients.

What will you gain by subscribing to our newsletter?

You can always get access to our newsletter by visiting the newsletter.wobit.com.pl page.

We respect your right to privacy and we protect your personal information. Your e-mail will serve us only to inform you about product novelties, events in which we will take part and participate, competitions, social actions in which we will engage, share our technical knowledge and what our company lives from one to the other newsletter.

According to art. 13 of the general regulation on the protection of personal data of 27 April 2016 (Journal of Laws UE L 119 of 04.05.2016; hereinafter: RODO) informs you that: